Boiler Manufacturers in India

Fourmax Vessels India Pvt. Ltd. is one of the leading Boiler Manufacturers in India, Suppliers and Exporters in India. Incorporated in 2023, we combine fresh innovation with solid industry know-how to deliver steam generation systems optimized for energy efficiency and longevity. With alternative names such as Steam Generator and Industrial Boiler, our products cater to heavy-duty applications across power plants, chemical processing, and manufacturing sectors.

Boiler Suppliers and Exporters in India

Fourmax Vessels India Pvt. Ltd. leverage manufacturing facilities near Pune to serve India’s industrial hubs. Our boilers are extensively used in petrochemical refineries, textiles, paper mills, and energy plants—sectors that demand consistent steam quality and minimal downtime. With a robust export program, we deliver turnkey solutions to international clients, facilitating smooth customs clearance and certified compliance with global boiler regulations.

Overview of the Boiler: Specifications, Types, Applications, and How It Works

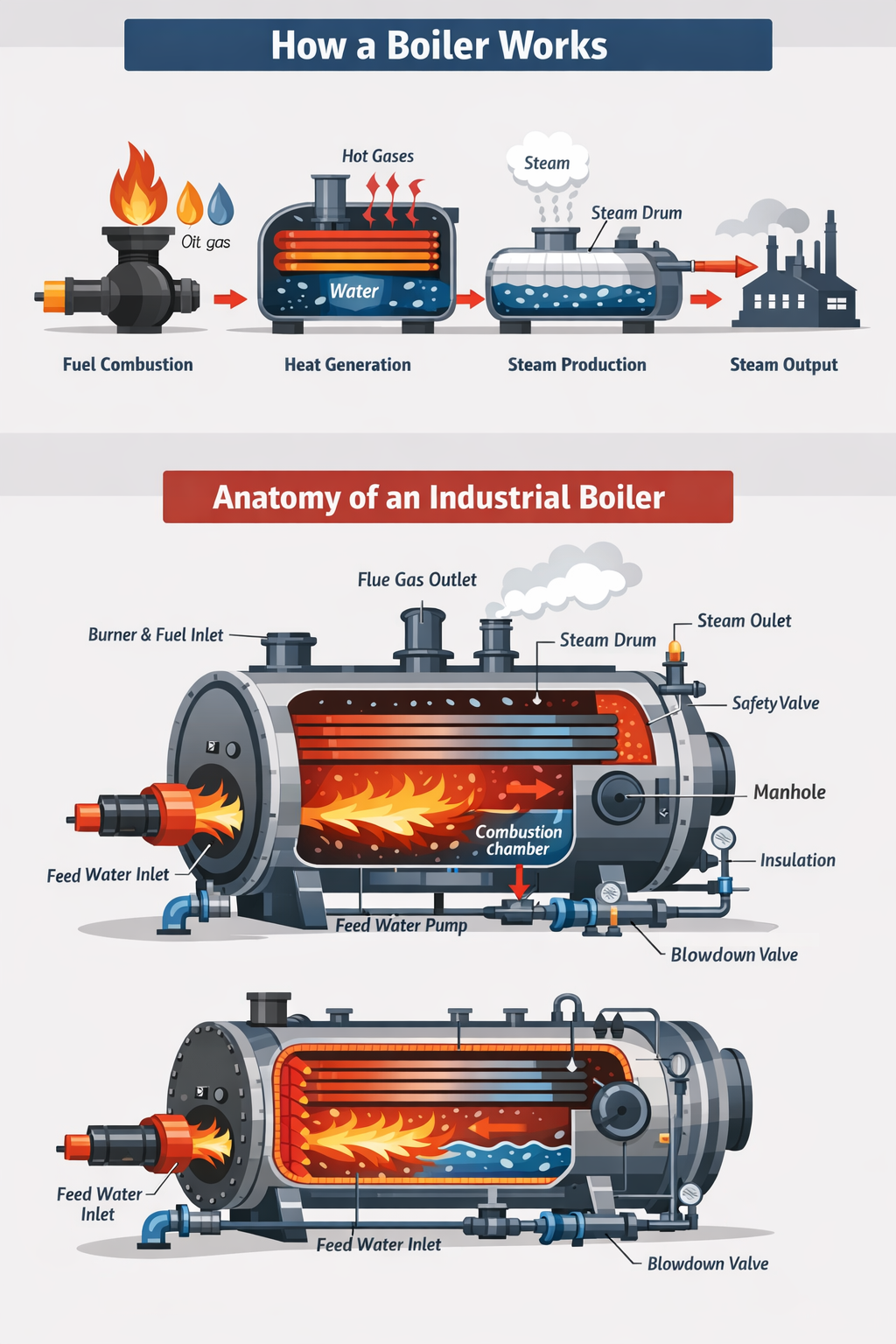

Boilers are engineered under IBR 1950 regulations and follow standards like IS 10496, IS 6533, and BIS Scheme II. They are designed for pressures up to 42 kgf/cm² using carbon steel or stainless steel, and operate on oil, gas, biomass, or dual fuels, achieving up to 90% efficiency with economizers. Equipped with safety valves, water-level gauges, and pressure gauges, boilers come in several types - fire-tube for low to medium steam needs, water-tube for high-pressure power generation, thermic fluid heaters for moisture-sensitive applications, and waste heat recovery boilers for enhanced plant efficiency. Common applications span power generation, chemical processing, food and beverage, and textile industries. Boilers work by igniting fuel in a burner to heat water, producing steam routed to equipment, with automated controls ensuring safe, efficient performance.

Types of the Boiler

- Fire-Tube Boilers: In this type, hot gases pass through tubes, and water surrounds the tubes. These boilers are mainly used for low to medium steam needs. They are affordable and easy to operate. Maintenance is simple, and they are known for their quick start-up time. Commonly used in small industries and heating systems.

- Water-Tube Boilers: Here, water flows inside the tubes, and hot gases heat the tubes from outside. They can handle very high pressure and large steam output. These boilers are perfect for power generation plants and large factories. They are more complex than fire-tube boilers but give better performance. Suitable for industries needing continuous and high-capacity steam.

- Thermic Fluid Heaters: These systems use heat transfer oil instead of water or steam. They are helpful where accurate and consistent temperature is required. Perfect for industries where steam can cause moisture-related issues. Common in chemical, textile, and food processing industries. They offer safe and dry heat with good energy efficiency.

- Waste Heat Recovery Boilers (WHRB): These are installed after gas turbines, engines, or furnaces. They capture and reuse exhaust heat that would otherwise be wasted. Help in saving fuel and improving the plant’s overall efficiency. Commonly used in cement, steel, and petrochemical industries. They also support environment-friendly operations by reducing emissions.

Specification of the Boiler

| Specification | Details |

|---|---|

| Regulation | IBR 1950 |

| Standards Referenced | IS 10496, IS 6533, BIS Scheme II |

| Design Pressure | Up to 42 kgf/cm² |

| Material | Carbon Steel / Stainless Steel |

| Fuel Type | Oil / Gas / Biomass / Dual Fuel |

| Efficiency | Up to 90% with economizer options |

| Safety Devices | Safety valves, water-level gauges, pressure gauges |

Applications of the Boiler

- Power Generation: Boilers are widely used in thermal power plants. They produce high-pressure steam by heating water. This steam is then sent to turbines, which rotate and generate electricity. As a result, boilers help in producing continuous and reliable power.

- Chemical Industry: In the chemical sector, boilers play a major role. They provide the heat energy required to run reactors and distillation columns. Boilers also help in heating fluids and gases in heat exchangers. Therefore, they support smooth and safe chemical processing.

- Food & Beverage Industry: Clean and hygienic steam is important in food processing. Boilers supply this steam for tasks like pasteurization, sterilization, and cooking. For example, milk and juice are pasteurized using boiler steam. Hence, boilers ensure product safety and quality in this industry.

- Textile Manufacturing: The textile industry needs steam for dyeing and finishing clothes. Boilers provide the correct amount of steam at the right temperature. This helps in getting the desired fabric quality and colour. So, boilers help in smooth textile production with precision.

Each application benefits from our custom-engineered designs that meet stringent safety and performance requirements.

How Boiler Works

The boiler’s burner ignites fuel, heating water either within tubes (water-tube) or around tubes (fire-tube). As water absorbs heat, it transforms into steam, which is routed via piping to the process equipment. Safety interlocks and controls maintain pressure, temperature, and water level within prescribed limits for reliable operation.

Why Choose us as a Boiler Manufacturers in India?

- Expertise: Our team blends 20+ years of industry experience in pressure vessels and control panels.

- Quality Assurance: We use premier-grade raw materials and follow ISO-aligned quality processes.

- Customization: Tailored solutions for unique process requirements and space constraints.

- Trust: Our clients include Thermax, Praj Industries, Forbes Vyncke, and Atlas Copco India.

- Global Reach: Efficient export logistics ensure on-time delivery worldwide.

Together, these strengths make us the preferred Boiler Manufacturers in India and Boiler Suppliers in India.

Get Boiler in India | Fourmax Vessels India Pvt. Ltd.

Fourmax Vessels India Pvt. Ltd. is a leading boiler manufacturers in India, suppliers & exporters in India, we ensure every unit meets IBR and BIS standards for peak performance and safety. Ready to upgrade your steam system? Request a quote today or download our detailed spec sheet to discover how our boilers can drive efficiency and reliability in your operations. Our team of experts is always available to provide guidance on selecting the right boiler for your needs, ensuring seamless installation and maintenance. With Fourmax, you gain not just a product, but a long-term partner committed to maximizing productivity and minimizing downtime. Experience unmatched quality, performance, and support with every boiler we deliver. Contact us for more information.

- Address: Ground Floor, Survey Number 21120 8A 8B, NA, Dehu Talwade Shiv Rasta, Viththalnagar, Dehugaon, Dehu, Pune – 412109, Maharashtra, India

- Phone: +91-8378966550

- Email: info@fourmaxindia.com

Each application benefits from our custom-engineered designs that meet stringent safety and performance requirements.

FAQs

We manufacture various types of industrial boilers including fire tube boilers, water tube boilers, and thermic fluid heaters. Our boilers are designed to meet diverse industrial requirements such as steam generation, heating, and process applications.

Yes, our boilers are designed and manufactured in accordance with IBR (Indian Boiler Regulations) and relevant BIS standards. We also provide third-party inspection and certification to ensure safety and regulatory compliance.

Our industrial boilers can operate on multiple fuel types including oil, gas, biomass, and dual-fuel systems. The fuel selection depends on efficiency requirements, availability, and specific industrial process needs.

Our boilers are widely used in textile, chemical, pharmaceutical, food processing, and power generation industries. They are designed to deliver reliable steam output and high thermal efficiency for continuous operations.