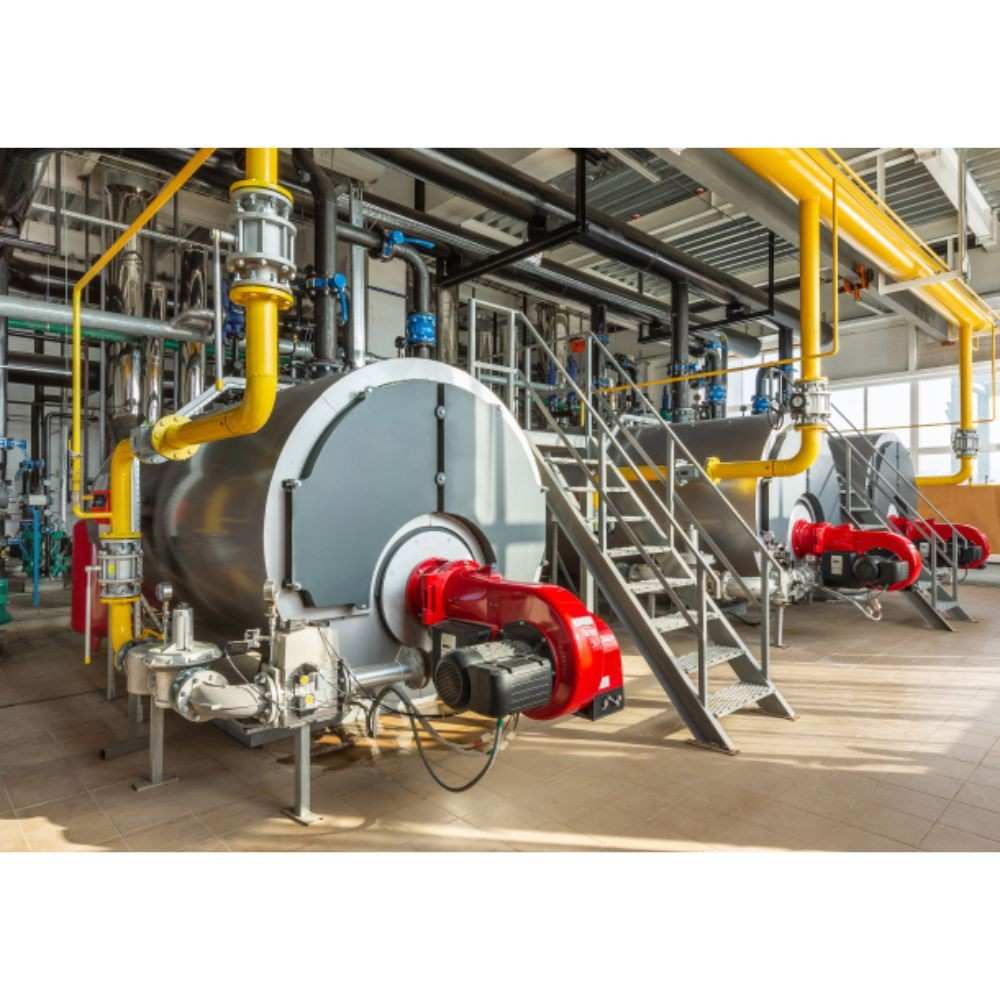

Boiler Pressure Part Manufacturers in India

Fourmax Vessels India Pvt. Ltd., is well-known Boiler Pressure Part Manufacturers in India, Suppliers and exporters in India, brings over two years of dedicated experience designing and fabricating pressure vessels. Moreover, Fourmax Vessels India Pvt. Ltd. is known for our expertise in pressure equipment-also referred to as pressure vessels or Boiler Pressure Parts-crafted to the highest industrial standards. As pioneers in the field, we combine robust engineering with innovative materials to deliver reliable solutions for power plants, petrochemical units, and other heavy‐duty applications.

Boiler Pressure Part Suppliers and Exporters in India

Fourmax Vessels India Pvt. Ltd. have expertise in Boiler Pressure Part Manufacturers in India and Boiler Pressure Part Suppliers in India, supplying critical components to industries nationwide. Our parts are installed in coal‐fired, biomass, and gas‐based boilers, where durability under cyclic stresses is crucial. Since our incorporation in 2023, we have manufactured, supplied, and exported over 500 metric tons of pressure parts, serving clients across India and beyond.

Overview of the Boiler Pressure Part: Specifications, Types, Applications, and how it Works

Fourmax Vessels India Pvt. Ltd. is a trusted manufacturer in India, supplier, and exporter in India, of high-performance Boiler Pressure Parts, We built our products as per IBR 1950 standards with IS 2002 carbon steel plates and IS 2003 seamless tubes. Designed to operate up to 42 kg/cm² pressure and 450 °C, components include steam drums, headers, bent tubes, economizer, and superheater coils, used widely in power plants, pharmaceuticals, oil & gas, and water treatment industries. With ISO 3834‑2 welding quality, rigorous non-destructive testing, and precision fabrication, these parts efficiently convert combustion heat into pressurized steam, ensuring safe, energy-efficient operations. Committed to custom solutions and compliance, Fourmax proudly serves industry leaders like Thermax and Forbes Vyncke. Contact us at info@fourmaxindia.com or +91 8378966550 to discuss your requirements.

What Is a Boiler Pressure Part?

A Boiler Pressure Part refers to any component of an industrial boiler that directly contacts steam or feedwater under pressure. These include drums, headers, tubes, and modules designed to withstand high temperatures and pressures. Each component adheres to IBR 1950 standards, ensuring structural integrity and operational safety throughout the equipment’s lifecycle.

Types of Boiler Pressure Part

- Boiler Drums (Steam/Mud Drums): First of all, Steam Drums play a key role in any boiler system. They help separate steam from water and also store water for continuous operation. Moreover, they are made using large-diameter shells and fitted with internal baffles. This design improves the steam-water separation and ensures smooth boiler performance.

- Headers: Next, we have Headers. These parts help distribute steam or feed water evenly across different circuits inside the boiler. Because of precision machining, the flow stays uniform. As a result, pressure drop is reduced, and the system works more efficiently.

- Bent Boiler Tubes: Then comes the Bent Boiler Tubes. These tubes are specially designed to fit into compact boiler layouts. Their bent shape helps in better heat transfer, even in limited spaces. In addition, we use a mandrel bending process, which keeps the tube wall thickness consistent and avoids any damage to the material.

- Economizer & Super heater Coils: Finally, there are Economizer and Superheater Coils. The economizer uses waste heat from flue gases to preheat the feed water. This reduces fuel consumption. On the other hand, the superheater raises the temperature of steam beyond saturation level, making it suitable for turbines and other equipment. Together, these coils help increase the overall efficiency of the boiler plant.

Specification of the Boiler Pressure Part

| Parameter | Specification / Standard |

|---|---|

| Design Code | IBR 1950 |

| Plate Material | IS 2002 Carbon Steel |

| Tube Material | IS 2003 Seamless Steel Tubes |

| Welding Quality | ISO 3834‑2 / BIS Equivalent |

| Inspection Methods | Radiography, Ultrasonic, Dye Penetrant |

| Maximum Allowable Working Pressure (MAWP) | Up to 42 kg/cm² |

| Operating Temperature Range | −10 °C to 450 °C |

Applications of the Boiler Pressure Part

- Power Plants: Firstly, in power plants, they help increase thermal efficiency. Whether the plant runs on coal, gas, or biomass, these parts make sure the boiler runs smoothly and gives better output.

- Chemical Processing: Secondly, in chemical processing, they support high-temperature operations. This includes reactors and distillation systems, where strong and safe pressure parts are important for continuous production.

- Pharmaceuticals: Next, in the pharmaceutical industry, they are used to create sterile steam. This steam is needed for clean-in-place (CIP) systems and sterilization, which helps maintain hygiene and safety.

- Oil & Gas: Moreover, in the oil and gas sector, these parts provide strong pressure control. They work well in refining heaters and heat recovery steam generators, ensuring safe and efficient operation.

- Water Treatment: Lastly, in water treatment plants, Boiler Pressure Parts are used in evaporators and clarifiers. They help in managing and treating industrial wastewater, making the process more effective and environment-friendly.

In short, these pressure parts are essential for industries that need reliable performance, high safety, and energy efficiency.

How Every Boiler Pressure Part Works

Boiler Pressure Parts convert thermal energy from combustion gases into pressurized steam. First, feed water enters the economizer coils, where it absorbs residual heat. Then, it passes through bent tubes within the furnace, transforming into a steam–water mixture. Finally, steam drums separate pure steam, which is routed through headers to turbines or process equipment, while water returns to the cycle.

Boiler Pressure Part Ordering, Compliance, and Safety Information

When ordering, please specify:

- Design code (IBR 1950 or API as required)

- Material grade and thickness

- Component type and quantity

All our products comply with IBR 1950 regulations and are certified under ISO 9001. We conduct full non-destructive testing (NDT) before dispatch.

Why Choose us as a Boiler Pressure Part Manufacturers in India?

- Expert Engineering: Years of experience in pressure vessel design ensure optimal performance.

- Custom Fabrication: Tailored solutions meet unique client specifications.

- Stringent Quality: All welding and materials meet ISO 3834‑2 standards.

- Energy Efficiency: Advanced coil and tube designs lower fuel consumption and operating costs.

- Trusted by Industry Leaders: We supply to Thermax, Praj Industries, Forbes Vyncke, Atlas Copco, and more.

As a result, we are Boiler Pressure Part Manufacturers in India, Boiler Pressure Part Suppliers in India, and Boiler Pressure Part Exporters in India.

Get Boiler Pressure Part in India | Fourmax Vessels India Pvt. Ltd.

Fourmax Vessels India Pvt. Ltd. is your trusted partner for Boiler Pressure Parts Manufacturers in India, Suppliers & Exporters in India. We are committed to excellence and safety, delivering products that meet stringent quality standards and ensure long-lasting performance. Our experienced team provides tailored solutions to meet your specific requirements, backed by reliable after-sales support. Partner with Fourmax to enhance efficiency, minimize downtime, and ensure the safe operation of your boiler systems. Trust us for precision, quality, and performance in every component we supply. To discuss your requirements or to Request a Quote,

Contact Us

- Address: Ground Floor, Survey Number 21120 8A 8B, NA, Dehu Talwade Shiv Rasta, Viththalnagar, Dehugaon, Dehu, Pune – 412109, Maharashtra, India

- Phone: +91-8378966550

- Email: info@fourmaxindia.com